| Sign In | Join Free | My chinacsw.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacsw.com |

|

Brand Name : TORICH

Model Number : EN10305-4

Certification : ISO9001, ISO14001 ,TS14969

Place of Origin : Zhejinag,China

MOQ : 3 tons

Price : 888USD PER TON

Payment Terms : T/T, L/C, D/A, D/P, Western Union, MoneyGram

Supply Ability : 18000 tons per year

Delivery Time : Within 30 days

Packaging Details : In Hexagonal bundles or wooden boxes packaging

Product name : Precision Seamless Steel Tube for High Pressure Oil Steam / Chemical Lines

Keyword : Precision Seamless Steel Tube

Surface : NBK

Usage : for High Pressure Oil Steam and Chemical Lines

Material : E215 E235 E355 ST52 ST37

Shape : Round

Length : 1-12m

OD : 5-420mm

WT : 0.5-50mm

Brand : TORICH

1.Quick Detail:

Black Phosphated Hydraulic Tubes with High Precision

EN10305-1, EN10305-4, DIN2391,

E235, E355, ST37.0, ST44.0, ST52.0

Steel Pipes with high precision for Hydraulic Systems Black Phosphating

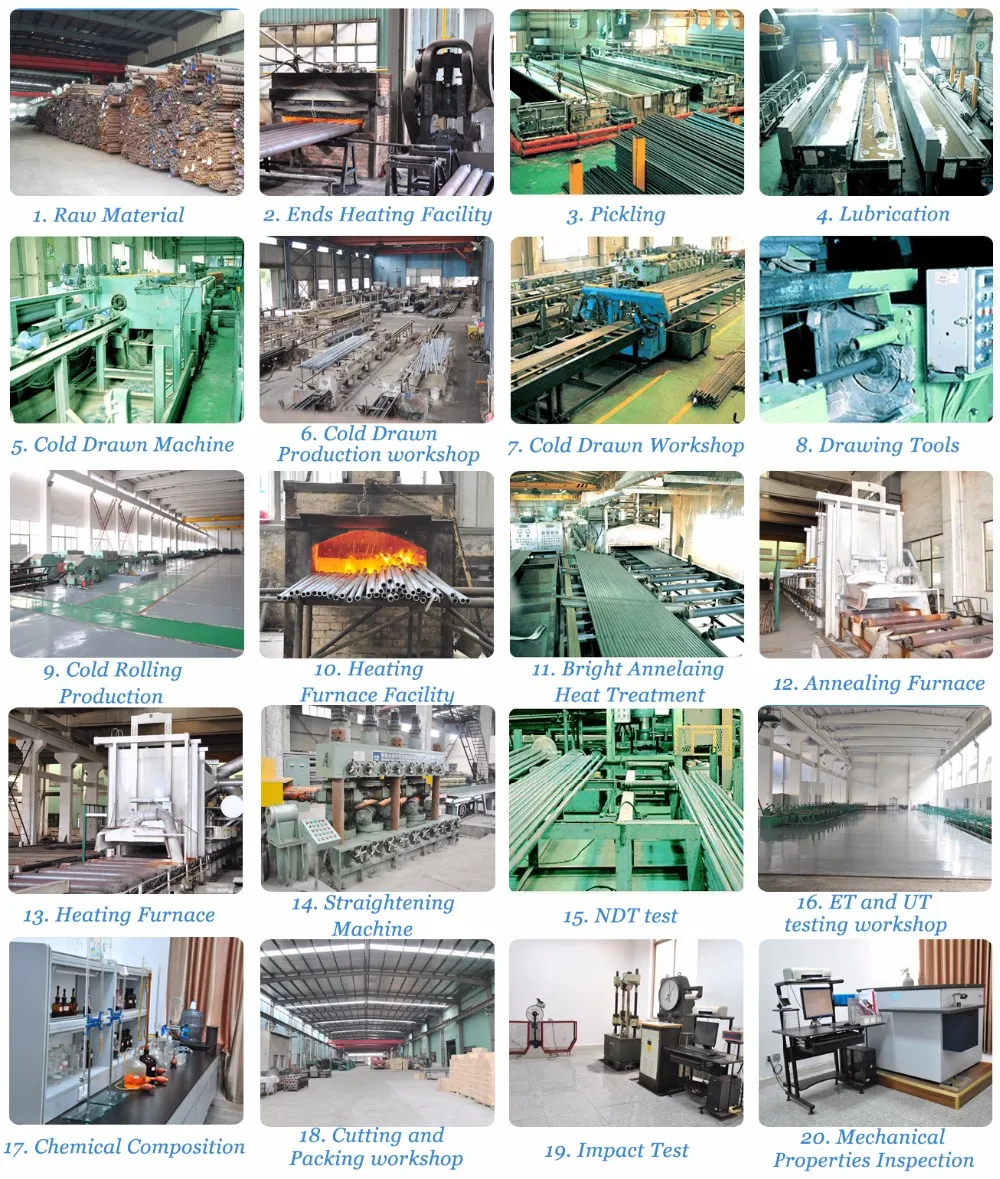

2.Production process:

DIN series tubes, cold drawn and bright annealed precision seamless steel tube is used as the tube to be phosphated. The phosphorization is realized with the imported chemical fluid to form a black film. The antirust oil is absorbed by means of the micropore on the film to prevent the tubes from getting rust.

3.Main Features:

Bright black color is homogeneously distributed on the tube surface. The tube has good property of antirust.

4.Main Application:

Phosphated hydraulic tube is mainly used in hydraulic system.

| Mechanical Properties of ASTM A519: | ||||

| Grade | condition | MPa Tensile point | Yield point | Elongation |

| 1020 | CW | ≥414 | ≥483 | ≥5% |

| | SR | ≥345 | ≥448 | ≥10% |

| | A | ≥193 | ≥331 | ≥30% |

| | N | ≥379 | ≥379 | ≥22% |

| 1025 | CW | ≥448 | ≥517 | ≥5% |

| | SR | ≥379 | ≥483 | ≥8% |

| | A | ≥207 | ≥365 | ≥25% |

| | N | ≥248 | ≥379 | ≥22% |

| 4130 | SR | ≥586 | ≥724 | ≥10% |

| | A | ≥379 | ≥517 | ≥30% |

| | N | ≥414 | ≥621 | ≥20% |

| 4140 | SR | ≥689 | ≥855 | ≥10% |

| | A | ≥414 | ≥552 | ≥25% |

| | N | ≥621 | ≥855 | ≥20% |

Delivery Condition:

1. BK (+C) No heat treatment after last cold forming process.

2. BKW (+LC) After last heat treatment there is a light finishing pass (cold drawing)

3. BKS (+SR) After the final cold forming process the tubes are stress relieve annealed.

4. GBK (+A) After the final cold forming process the tubes are annealed in a controlled atmosphere.

5. NBK (+N) After the final cold forming process the tubes are annealed above the upper transformation point in acontrolled atmosphere.

5.Our products are widely used in:

Engineering machinery Machine tool industry Hydraulic industry Special vehicle

Automobile pipeline Heavy machinery Compressor Shipbuilding industry

Railway locomotive Diesel engine Utility boiler Injection molding machine

Power equipment Heavy duty automobile Forging and stamping machine

6.Main Characteristics:

No Oxidation Layer on the Outer and Inner Walls

No Crack under Flaring and Flattening

No Leakage under High Pressure

No Distortion after Cold Bending

High Precision High Cleanness Excellent Brightness

A: A professional steel pipes materials inventor, manufacturer and solution provider

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us

|

|

Precision Seamless Steel Tube for High Pressure Oil Steam / Chemical Lines Images |